The ceiling panel of a Delta Airlines Boeing 767 aircraft got detached on a flight from Honolulu to Minneapolis.#Boeing #BREAKING pic.twitter.com/XbyVSdjR0n

— Target Reporter (@Target_Reporter) June 5, 2024

The craziest part about this whole Boeing thing is that there is still not any kind of serious government investigation into just what the hell is going on at this company.

I wonder if that is related to how much they provide in campaign donations?

Two former employees of Boeing and its key contractor have told The Post that — despite the deaths of two whistleblowers within two months this year — they are more determined than ever to tell the truth about what they allege are dangerous practices at the once-great but now-scandal-scarred manufacturer.

Roy Irvin, a veteran of Boeing, and Santiago Paredes, who worked at Spirit AeroSystems (not to be confused with Spirit Airlines), are just two of at least 20 whistleblowers in the process of making their concerns about safety and quality issues at the aerospace giant public.

Their testimony comes after years of Boeing being dogged by whistleblower testimony and congressional investigations.

A scathing House Transportation and Infrastructure report in September 2020 found that two 737 MAX crashes in 2018 and 2019 were the “horrific culmination” of “repeated and serious failures” by the company and regulators.

Then in January, a fuselage plug blew off a new Alaskan Airlines Boeing 737 MAX-9 at 10,000 feet.

A whistleblower told the Seattle Times that the fault lay with Boeing because after the fuselage was delivered by its manufacturer, Spirit, a panel had been removed at Boeing’s Renton, Washington, factory and reinstalled without four crucial bolts.

Now Irvin and Paredes are speaking out.

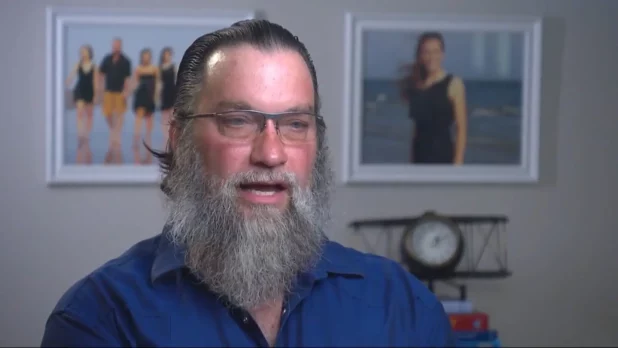

Roy Irvin

From 2011 until 2017, Irvin was a quality investigator at Boeing in North Charleston, SC, trying to ensure that $250 million 787 Dreamliner planes were ready to be put to work before they left the factory. He began at the company in 2009.

Irvin said he “pushed back” almost every day at serious safety and quality issues he found on planes that had left the factory floor and were on the “flight line,” meaning they were supposed to have been checked and found to be good to go.

Paredes was a production inspector for Spirit AeroSystems for 12 years before leaving in 2022.

He told The Post he was shocked when he arrived at the company and, he alleges, saw hundreds of defects on the production line. He was even more horrified, he said, when he was pressured not to say anything.

“I was at the end of the production line and so I was supposed to be looking at the finished product before they shipped it to Boeing.” Paredes said.

“Instead I saw missing parts, incomplete parts, frames that had temporary clamps and missing fasteners, dents in the parts, damaged parts, cut rivets, issues that might occur but should be fixed before they got to me.

“Everything I was seeing was like a ticking time bomb.”

It is a ticking time bomb.

At any point, a massive disaster could happen that kills hundreds of people, and then you’re going to have no real choice but to ground most or all Boeing jets. This is going to increase the cost of plane tickets by at least 20x, maybe even more. It’s basically going to make air travel impossible for normal people, indefinitely.

Maybe that was the plan all along…?